Murphy & Read provides custom manufactured and standard extension springs, precisely manufactured to meet your stringent tolerances and specifications. Our advanced facilities handle both high-volume custom orders and short-run or prototypes offering custom materials, end treatments, surface finishes, and exact tolerance control.

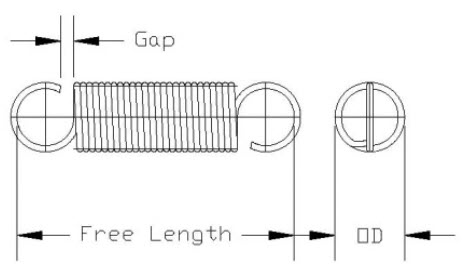

Our stock extension springs have outside diameters ranging .063″ – 1.25″ and Free Length From .250″ – 7.50″. The loops are either cross center or machine.

If you require a custom spring we can make virtually any design, our custom capabilities allow for free length from .100″ to 50′. If you need design help we have a responsive and experienced staff of engineers. Or check out the technical resources section of our website for almost everything spring related.

Buy Springs

What is an Extension Spring?

- Functionality and Applications: Extension springs, also known as tension springs, are helical coiled springs designed to resist pulling forces. Unlike compression springs, which shorten when a load is applied, extension springs elongate under tension. They store energy when stretched and exert a pulling force to return to their original length once the force is removed. Extension springs are characterized by their initial tension, which is the force required to overcome the internal pre-load and begin separating the coils. They find widespread use in various applications requiring a pulling or return force, such as screen doors, trampolines, weighing scales, and tensioning devices. Other common uses include: counterbalance mechanisms, linkages, retractable mechanisms, and load balancing systems.

- Material Selection and Performance: Similar to compression springs, extension springs can be manufactured from a variety of materials to suit specific application requirements. Common materials include music wire (high strength and good fatigue life), spring steel (various grades offering different strength and flexibility), stainless steel (excellent corrosion resistance for harsh environments), and alloy steels (for high temperatures or specialized mechanical properties). The choice of material significantly influences the spring’s strength, elasticity, durability, corrosion resistance, and performance under specific operating conditions. Factors like wire diameter, coil diameter, number of coils, and the initial tension are crucial design parameters that determine the spring’s load-deflection characteristics and overall performance.

Specific Applications

- Precision Measurement Instruments: Used in sensitive weighing scales, force gauges, and calibration equipment where accurate and repeatable tensile forces are required for precise measurements.

- Actuators and Linkages: Employed in precision linear actuators and mechanical linkages where controlled extension and retraction are necessary for precise positioning and movement in robotic or automated systems.

- Tensioning Mechanisms in Optics: Utilized in optical instruments and laser systems to maintain precise tension on fibers, mirrors, or lenses, ensuring accurate alignment and performance.

- Medical Device Actuation: Found in certain medical devices requiring controlled and reliable pulling forces for actuation, such as in specific surgical instruments or drug delivery mechanisms.

- High-Performance Valves: Used in specialized valves where precise control of opening and closing forces is critical for regulating fluid or gas flow in sensitive systems.

- Robotics and Automation: Integrated into robotic arms and automated machinery to provide controlled pulling forces for gripping, manipulating, or returning components to specific positions with high accuracy.

- Semiconductor Manufacturing Equipment: Employed in delicate machinery used in semiconductor fabrication where precise tensioning or retraction of components is crucial for the manufacturing process.

- Aerospace Control Systems: Utilized in certain aerospace mechanisms where reliable and precise tensile forces are required for the operation of control surfaces or other critical components.

Interactive CAD Spring Configurator

Need a CAD drawing? Try our free CAD configurator tool to produce standard or custom spring models.

Extension Spring Materials

We use a range of spring materials to meet the needs of our diverse customer base. Here are the materials we use most often and their maximum recommended % tensile:

| Common Spring Materials | Max Recommended % Tensile | |

|---|---|---|

| St | Sb | |

| Music Wire | 45 | 75 |

| Chrome Silicon | 45 | 75 |

| Chrome Vanadium | 45 | 75 |

| 302 Stainless Steel | 35 | 55 |

| 316 Stainless Steel | 35 | 55 |

| 17-7 Stainless Steel | 45 | 75 |

Resources

Comprehensive Technical Resources

Our technical resources section is a valuable repository of information on compression spring design, materials, and applications. You’ll find:

- Spring design calculators and formulas

- Material selection guides

- Glossary of spring terminology

- Application-specific case studies

- CAD files of common spring types.

- White papers and articles on advanced spring technologies.

Engineering Support

Our team of experienced spring engineers is available to provide expert design assistance. Whether you need help selecting the right material, calculating spring rates, or optimizing your design for performance and cost-effectiveness, we’re here to help. We offer:

- Design consultations

- Prototyping services

Extension Spring Terminology

| Abbreviation | Meaning |

|---|---|

| OD | Outside Diameter |

| D | Mean Diameter |

| d | Wire Diameter |

| Na | Number of Active Coils |

| R | Spring Rate |

| P | Applied Force |

| St | Torsional Stress |

| Sb | Bending Stress (in loops) |

| IT | Initial Tension |

| c | Spring Index |

| ΔL | Deflection |

| XLP | Cross Center Loops |

| MLP | Machine Loops |

| UTS | Ultimate Tensile Strength |